The deacidification process stabilizes paper, but it cannot restore lost physical properties. Once paper has deteriorated to a state of brittleness, it needs reinforcement to protect it against fracture. The earliest technique employed for supporting brittle paper was silking. A starch paste or paraffin wax was used to sandwich paper between sheets of finely woven silk. After several decades of extensive use, silking was gradually supplanted by cellulose acetate lamination. Although some proponents of lamination maintained that silk deteriorated after about 20 years, a number of documents silked around the turn of the century are still in excellent condition. Many of these documents were repaired so skillfully that the silk layers cannot be easily discerned by an unpracticed eye.

Cellulose acetate lamination was developed in the 1930s by scientists at the National Bureau of Standards. Paper sandwiched between two thin sheets of cellulose acetate film was heated under pressure in a hydraulic press. Later William Barrow designed a lamination press in which paper was first heated between sheets of cellulose acetate and then pressed between polished rollers. To strengthen the paper further and eliminate the unaesthetic sheen of cellulose acetate, Barrow also incorporated fine layers of tissue paper on either side.

Cellulose acetate lamination not only imparts renewed strength, but when preceded by deacidification can extend indefinitely the life of an embrittled paper. Since it is a mechanized process, it can provide high output at a limited cost. This seeming advantage, however, can become a potential hazard to the documents. The risk comes from an assembly line operation in which documents do not receive individual attention but are indiscriminately laminated without regard to the nature of paper or inks.

Lamination techniques using very fine tissue paper with acrylic adhesives for bonding have been developed in recent years, but the technique that appears to find most favor with paper conservators is polyester encapsulation, which was developed at the Library of Congress. In this simple procedure, paper is sandwiched between two sheets of mylar or other polyester film, which are sealed around the edges. Polyester encapsulation is popular because it is easily reversible: there is no adhesion between paper and the plastic film. Thus it is more in tune with the contemporary conservation philosophy of doing as little as possible to alter the essential nature of the object in need of protection. Lamination still has a place in preservation, especially in high-volume applications, but it must be used judiciously.

Encapsulation and lamination are useful for supporting single sheets, but they have only limited applicability to books. Books can be unbound and the individual leaves encapsulated or laminated before being rebound, but this is an expensive process which cannot be applied to millions of volumes in a general collection. Can a chemical process be developed that will strengthen the brittle paper of old books?

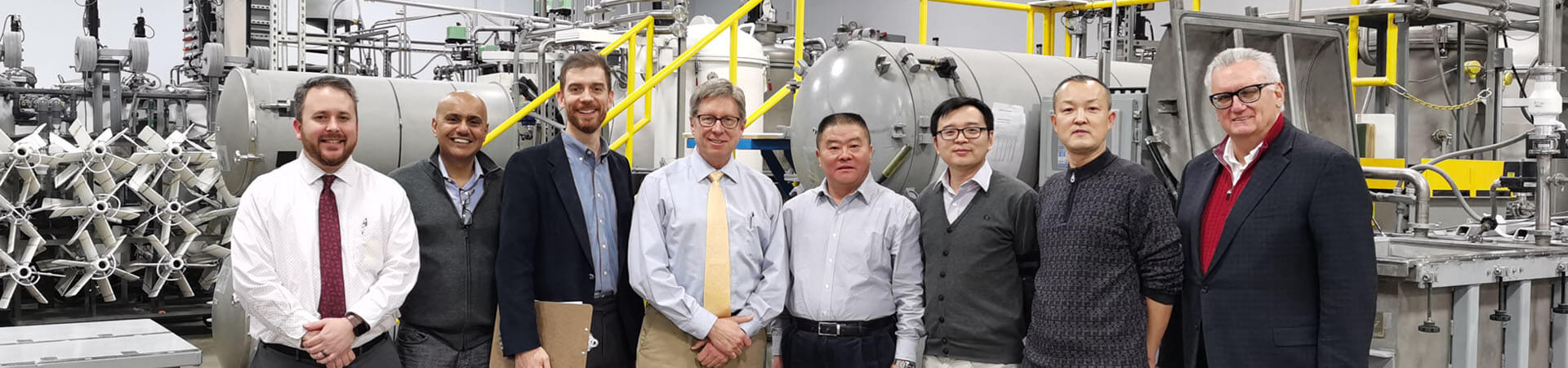

Three different approaches are being actively pursued. Bruce Humphries at the Nova Tran Corporation has used a parylene coating – employed by industry to protect electronic parts – to strengthen papers in a book, as well as other objects such as insect specimens in museums. The main drawback of parylene coating is its high cost. The British Library is developing a technique which involves joining the shortened cellulose chains in brittle paper to another polymeric molecule through a graft copolymerization process. The technique has been successfully applied in the laboratory, and construction of a plant is being considered. The National Library of Austria employs a bulk process for strengthening newsprint. Newspapers are impregnated in an evacuated chamber with an aqueous solution containing methyl cellulose, polyvinyl acetate, and calcium or magnesium salts. The soaked newspapers are then freeze-dried.