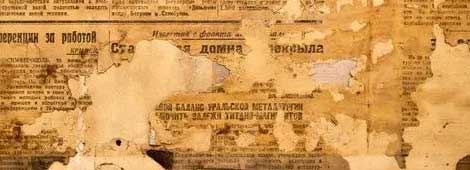

In 1930, William Barrow concluded that paper itself deteriorated over time and that, without the proper control of its acidity level, the contact with the light itself can wear out and affect the composition of paper. Thus, it becomes important that the paper has a neutral (or basic) chemical composition, with a pH equal to or slightly higher than 7.0.

The manufacturing process of this paper implies the treatment with calcium carbonate (which is called an alkaline reserve) that neutralizes the acids naturally created by cellulose. In this way, it can be ensured that papers with this treatment maintain their alkalinity for at least 100 years, favouring the conservation processes of the paper. However, if you want to conserve albumins, chromogenic or dye-transfer processes, paper with an alkaline reserve is not recommended because it can react with the compounds in the paper.

Another important detail is to guarantee that the paper is equally free of lignin. Lignin is a chemical compound naturally present in cellulose, whose oxidation acidifies and stains the paper. It is the main responsible for the appearance of yellow spots.

How to identify acid free paper?

Acid free paper generally presents a quality certificate where you can read its main characteristics and tests to which it has been subjected. In some cases, standards such as ISO18902 and ISO18916 are specified, but it is not crucial they be mentioned.