Introduction

The investigation into a new non-aqueous deacidification system for use in single item treatments was based on the premise that deacidification benefits paper based materials and that a conservator's acceptance of these benefits can be compromised by dissatisfaction with currently available non-aqueous methods. The decision to explore the efficacy of the Bookkeeper spray system was supported by encouraging results in the Bookkeeper Mass Deacidification System research1. The goals were to clarify the extent of benefits and risks associated with Bookkeeper and to develop a protocol for selection, testing and treatment of rare and special collection materials.

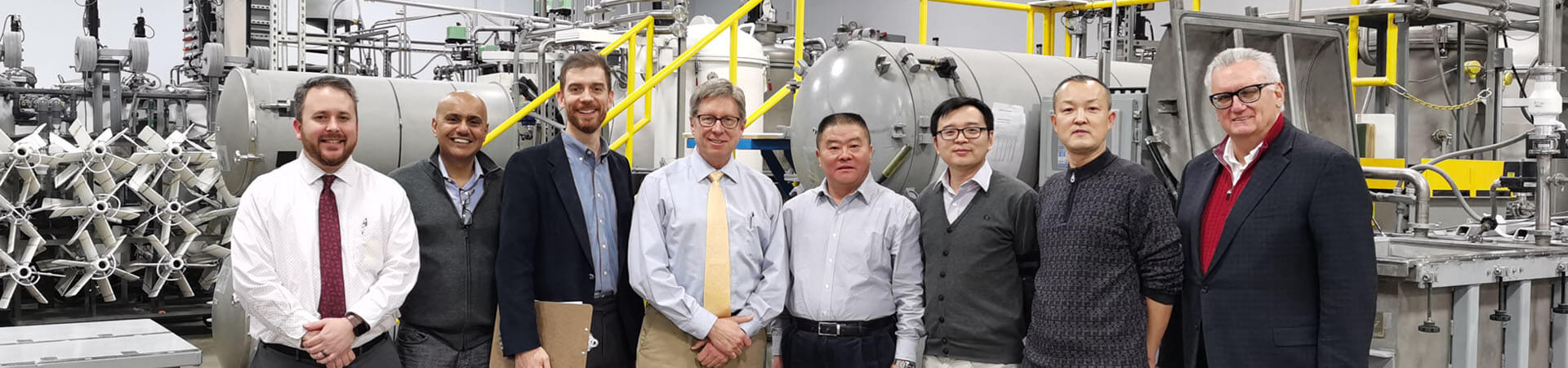

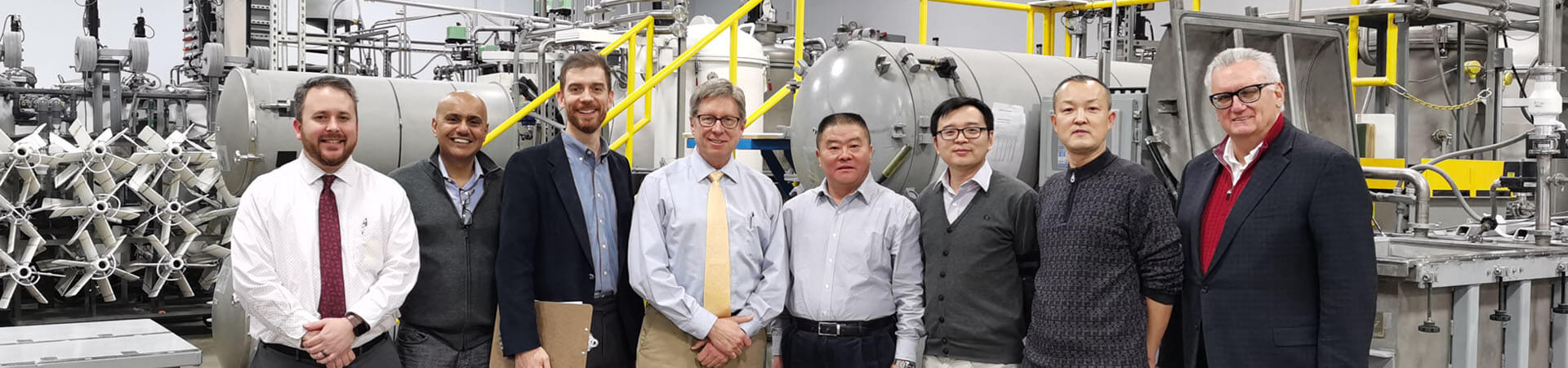

Several tests were developed while working closely with Dr. Chandru Shahani, Chief, Preservation Research and Testing Division, Ken Harris, Preservation Projects Director, and the Library's Preservation Research and Testing Laboratory staff. These tests were designed to determine the efficacy of the product when applied by spray to single items through measurement of the quantity of alkaline reserve deposited by the spray, the uniformity of the spray application, the speed and extent of the reaction, the amount of penetration or migration possible, and any effect on media.

The Decision to Deacidify

Although much information and knowledge exists regarding the benefits and risks of deacidification, many conservators have not found it easy to interpret and use that information in a consistent manner. Conservators are responsible for the immediate and long term consequences of deacidification treatments, and naturally have reservations about performing treatments which cause unacceptable alterations in the object even though treatment may prolong the life of the object. Physical and chemical alterations are direct consequences of treatment; therefore the intention is to use methods which provide the highest level of benefit while posing the least amount of risk to the object. In the past, potential negative effects of deacidification have manifested themselves as yellowing, textural change or color shift. Understandably, reluctance to deacidify leads some conservators to rely on good housing and storage in lieu of deacidification. These remedies may be appropriate for specific situations; however, they are only partial solutions and do not provide maximum benefit for many objects. Treatment decisions require accountability and need to thoroughly address the real consequences, including the long term costs of partial or sub-optimal treatment solutions. The Bookkeeper spray product is a viable option because testing shows that the chemistry appears to work as theorized with few unwanted side effects.

The treatment referred to as "deacidification" actually describes two different situations: one, the removal of acids, by-products and neutralization of remaining acids, and two, the deposit of an alkaline material which neutralizes the acids and leaves an alkaline reserve. When the need for deacidification is indicated as part of a treatment strategy the conservator must choose between aqueous and non-aqueous methods. In either system, water is necessary for deacidification to occur. The most benefit to the cellulose chain can be gained from aqueous processes because through immersion, water soluble acids and their by-products are actually washed from the paper at the same time that neutralization and deposit of an alkaline reserve occurs. Where aqueous treatment is not possible, neutralization and deposit of an alkaline reserve can still be achieved using a non-aqueous process. Non-aqueous systems all rely on the natural moisture content of the paper and ambient humidity to allow the neutralization reaction to proceed. There are several non-aqueous deacidification systems available. All of these pose concerns for the object, the conservator and the environment. Additionally, some of the chemicals are costly and face government restrictions on usage and disposal. Various formulations have been known to leave an odor or visible surface deposit, cause changes in media solubility or color, cause discoloration of paper, or alter the feel and drape of a sheet. (Bookkeeper does not leave an odor on treated objects, but in some cases a velvety feel is evident when handling treated paper.) Furthermore, the unpredictable effects of application method and equipment also influence the conservator's willingness to deacidify. A particular concern has been the question of "preferential aging", or spots and streaks caused by uneven deposits which age at different rates and are thought to create areas of varying strength and weakness. Aging tests looking for evidence of application methods on preferential effects have not been completed as of this publication.

In 1993 and 1994 the Library contracted with a team of technical experts to evaluate the effects of deacidification with the Bookkeeper mass system. Standard Library of Congress blue test books and a wide variety of bound volumes representing typical Library collection materials were treated by immersion in Bookkeeper. The blue books were then examined, aged and tested for physical endurance. The testing showed that Bookkeeper deposited an adequate alkaline reserve and the treated samples sustained greater fold endurance and tear strength compared to untreated samples. Evaluation of the book components of every test volume (cover, materials, titling, binding, paper, media, etc.) revealed a uniform deposit and no unacceptable evidence of treatment. Since 1995, about 150,000 books at the Library of Congress have been treated with the mass process. The Bookkeeper Spray system has been in use for the last few years on a wide range of collection materials at a growing number of institutions worldwide.

The Bookkeeper non-aqueous deacidification method uses a non-toxic, inert liquid (perfluoroalkane), containing sub-micron sized particles of magnesium oxide with the addition of a surfactant ( a perfluoropolyether derivative) to aid in the dispersion of the particles. When the product is sprayed onto the object, the carrier and surfactant rapidly evaporate and magnesium oxide particles remain lodged in the paper fibers. The acid neutralization process begins, in theory, when ambient moisture or water inherent in the paper reacts with the magnesium oxide to form magnesium hydroxide.